Business pain points

The processing data is large and the error rate is high

The design of the business interface is lagging behind and the operation is inconvenient

Cross-system integration is difficult

Business Highlights

Multiple types of RPA bots fully cover business systems

RPA helps the transformation and upgrading of the manufacturing industry

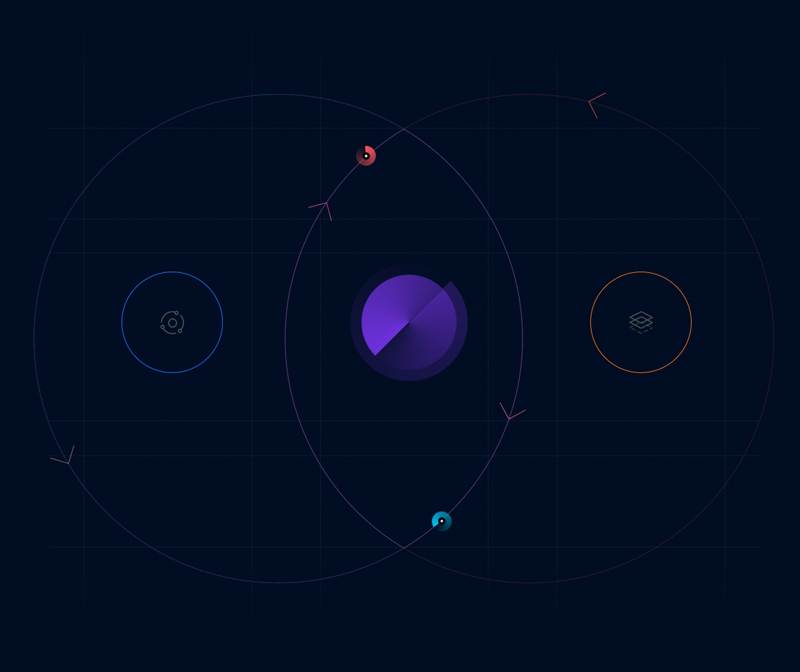

Solution

Through the introduction of i-search RPA robot, the following processes have been successfully automated: ERP system login, data query, report generation, and processing of insufficient materials. Compared to traditional manual processing, tasks that originally took 210 minutes to complete can now be completed in only 60 minutes, which not only saves 40% of labor costs, but also improves overall process efficiency by 71%.

Automation

Automation

Bank

Bank

Insurance

Insurance

Logistics

Logistics

Discovery and Evaluation

Discovery and Evaluation Industry Solutions

Industry Solutions  General Solutions

General Solutions Partnership

Partnership Ecosystem Alliance

Ecosystem Alliance Consulting Services

Consulting Services  Community

Community  Company Introduction

Company Introduction News and Updates

News and Updates Contact Us

Contact Us